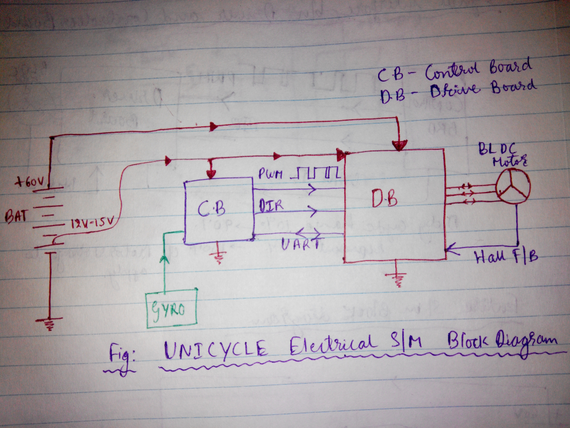

Control board and Driver board interface

(Referring to the figure attached)

Functionality of each board in brief.

Control Board(CB):

> Reads the signal from the Gyro and calculates the voltage to be applied to the motor using closed loop control.

> Sends this voltage to the Driver board.

Driver Board(DB):

> Decodes the voltage value communicated by CB and applies it to the BLDC motor in the right direction.

The attached image shows the

>Power distribution and

>Signal Interface

between different components.

How should CB communicate with DB????

- The figure shows 2 ways to communicate.

1) PWM and Direction (DIR)

With these 2 lines CB can send voltage and Direction info to the drive.

> Voltage is sent in the form of PWM signal with Duty Cycle changing from 10% (0V to motor) and 90%(Max 60V to motor)

> Direction is sent in the form of binary for CW or CCW.

Pros:

-Less processing either side.

Cons:

-Only voltage and DIR can be communicated.

-Unidirectional

2) UART (Tx and Rx)

>Voltage and DIR info can also be sent using UART lines.

>Data needs to be packed in a particular format in CB and sent to DB.

Pros:

- Data can be bidirectional.

DB can send other data like Motor current and Error status of DB.

Cons:

- Adds processing delay in packing and decoding the data.(in both CB and DB)

- Serial communication itself will have the delay of sending data bit after bit.

So which is best for Volt and DIR communication??

>Among these shortlisted 2 options we need to choose anyone to start with based on some calculations and simplicity to implement.

-Though technically both are simple to implement PWM and DIR method will take less time to complete.

To get the benefit of PWM & DIR(METHOD -1) method over UART (METHOD -2) we need to select the appropriate PWM frequency.

Minimum of 1Khz has to maintained to gain the control loop effectiveness at 1Khz.

Comments